Automotive industry

Laser machines: a force for innovation in automotive manufacturing

In the highly competitive and rapidly evolving automotive manufacturing industry, where every process upgrade can be the key to market share, Udibo Industrial Machinery has developed and manufactured laser welding machines, laser cleaning machines, laser marking machines and laser cutting machines that have been deeply integrated into all aspects of automotive manufacturing, bringing the industry more efficient and precise production solutions for the industry.

Laser welding machine: the strong bond of the car body

The welding quality of an automobile body directly affects the safety and overall performance of the vehicle. In the body welding workshop of a well-known automobile production factory, a car body is being assembled and welded on the assembly line. Although the traditional resistance spot welding is widely used, but there are uneven strength of the welded joints, slow welding speed and other issues. The Udibo laser welding machine shows great advantages, it can achieve continuous, high-speed welding, weld seam strength than the traditional spot welding increased by 15%. When welding roof-to-body joints, the laser welder creates beautiful, strong welds that not only improve the overall strength of the body, but also optimise the aerodynamics of the body and reduce wind noise when the vehicle is in motion. After adopting our laser welding machine, the automobile manufacturer's body welding efficiency increased by 30%, and the body rigidity test pass rate increased from 80% to 95%.

Laser cleaning machine: parts clean environmental protection guardian

Automotive parts in the processing and assembly process, the surface will remain oil, impurities and processing debris and other pollutants, these impurities will affect the performance and service life of parts. In an automotive engine parts manufacturing plant, the surface of a newly machined engine block is covered with oil and metal debris, which is instantly removed by a Udibo laser cleaner using a high-energy laser beam. Compared with traditional chemical cleaning methods, laser cleaning does not require the use of chemical reagents, to avoid the pollution of chemical waste liquid on the environment, but also will not cause corrosion on the surface of the parts. The cleanliness of the cleaned engine block surface reaches the industry's high standard, effectively improving the assembly quality and performance stability of the engine. According to statistics, the use of laser cleaning machine, the enterprise's engine parts scrap rate reduced by 20%, the subsequent assembly link failure rate also dropped significantly.

Laser marking machine: a reliable partner for product traceability

In the process of automobile manufacturing, accurate marking and tracing of parts is an important part of quality control. On the automotive wheel production line, Udibo laser marking machines are marking each wheel with a unique identification code, including production date, batch number, product model and other information. These markings are etched into the wheel surface by laser, creating a permanent marking that will not fade or wear off, even after long periods of use and harsh road conditions. In the case of automotive recalls, the identification code marked by the laser marking machine enables companies to quickly and accurately locate the problematic parts, which greatly shortens the recall processing time and reduces the cost of the recall. In addition, in the production of automotive interior parts, laser marking machine can also be used for brand logo and pattern engraving, to enhance product aesthetics and brand recognition.

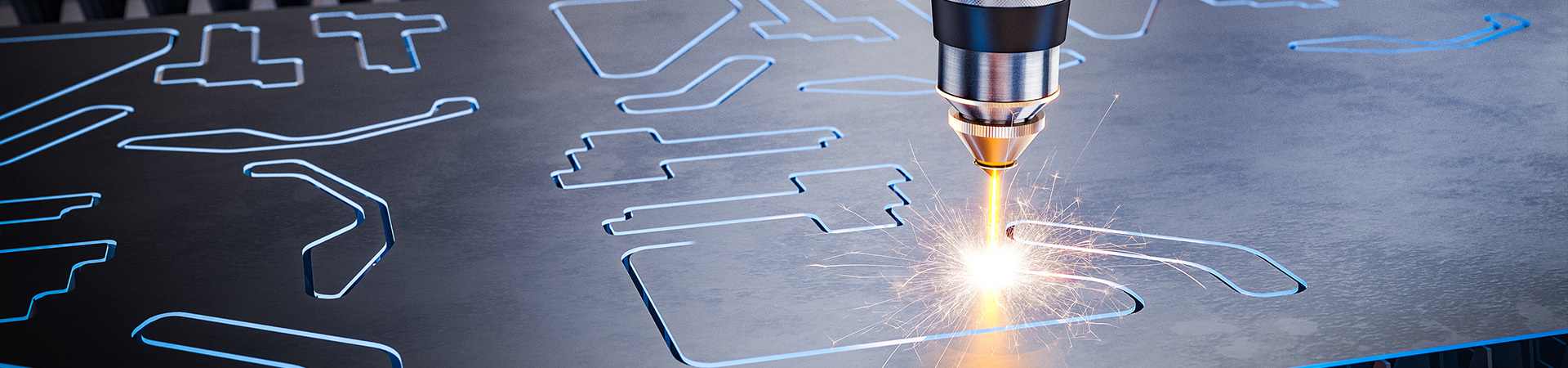

Laser Cutting Machine: Precision Carver for Complex Components

Automotive manufacturing requires a large number of complex shaped parts, such as automotive seat skeleton, door panels, etc., the cutting precision and quality requirements are extremely high. At an automotive parts processing plant, a Udibo laser cutter is being used to cut high-strength steel plates to make car seat skeletons. Traditional press cutting methods not only have high tooling costs, but also have limited cutting precision, making it difficult to meet the demands of processing complex shapes. By precisely controlling the energy and path of the laser beam, the laser cutting machine is able to achieve burr-free, high-precision cutting, with a cutting accuracy of ±0.1mm, and the cut seat skeleton can go directly to the subsequent welding and assembly processes without secondary processing. After adopting the laser cutting machine, the production cycle of the automotive seat frame of this enterprise has been shortened by 40%, and the utilisation rate of raw materials has been increased by 25%, which effectively reduces the production cost.

As a reliable technology partner for the automotive manufacturing industry, Udibo Industrial Machinery will continue to invest in research and development to continuously improve the performance and quality of our laser machines. We believe that our laser machine series can help automotive manufacturers to improve production efficiency, optimise product quality, reduce production costs and stand out in the competitive market. If you are looking for advanced processing solutions in the automotive manufacturing field, Udibo is looking forward to working with you to create a better future for the automotive manufacturing industry.

Application scenarios

Aerospace-industry

Automobile-manufacturing-industry

Energy-industry

Household-electric-appliance-industry

Metalworking-industry

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Recommend Product

Contact Us

Phone: +86 (China) 152-5267-7152

WhatsApp: +86 (China) 152-5267-7152

E-mail:info@udibomfg.com

Address: Building 1002 Redstar International Technology Park, Mudu Town, Wuzhong District, Suzhou City, Jiangsu Province, China