Printing and Packaging Industry

Laser machines: a tool for innovation in the printing and packaging industry

In the printing and packaging industry, efficiency, precision and innovation are the key elements for companies to gain a foothold in the market, and Udibo Industrial Machinery, with its deep knowledge of laser technology, develops and manufactures laser welding machines, laser cleaning machines, laser marking machines and laser cutting machines, which are gradually becoming an important force for the transformation and upgrading of the printing and packaging industry.

Laser welding machine: packaging containers manufacturing solid protection

In the production process of packaging containers, the sealing and strength of the container is crucial. In a large plastic packaging containers manufacturing plant, is producing plastic drums used to contain liquid food. Traditional welding methods are prone to problems such as weak welds and poor seals, leading to an increased risk of product leakage. the Udibo laser welding machine uses a high-energy-density laser beam to accurately weld the body and lid of plastic buckets. The laser welds are uniform and strong, providing a 50% improvement in sealing compared to traditional welding methods, effectively preventing liquid leakage. In addition, the laser welding is fast and the production efficiency is 40% higher than before. After adopting our laser welding machine, the scrap rate of plastic packaging containers of this enterprise was reduced from 10% to 3%, which greatly reduced the production cost.

Laser cleaning machine: printing equipment maintenance of efficient helpers

After a long period of use, printing equipment, cylinders, printing plates and other key components will accumulate pollutants such as ink, paper dust and dust, which will affect the printing quality and lead to blurred images, colour deviations and other problems. In the equipment maintenance workshop of a large printing plant, the cylinders of a long-used offset press were covered with thick layers of ink and dirt, and the Udibo laser cleaner was able to quickly clean the surface of the cylinders without dismantling the equipment, by precisely controlling the laser beam. Compared to traditional chemical cleaning and manual wiping methods, laser cleaning is not only more efficient, reducing cleaning time by 70%, but also prolongs the life of the equipment by not damaging the cylinder surface. After using the laser cleaning machine to maintain the printing equipment, the factory's printing products defective rate reduced by 35%, the printing quality has been significantly improved.

Laser marking machine: a reliable partner for product identification and anti-counterfeiting

In the printing and packaging industry, product identification and anti-counterfeiting are crucial, which not only help brand promotion, but also effectively prevent counterfeiting. On the production line of a well-known cosmetic packaging printer, Udibo laser marking machines are marking cosmetic boxes with beautiful brand logos, product names, production dates and anti-counterfeiting QR codes. These logos are permanently marked by laser etching, which is clear, wear-resistant and has unique anti-counterfeiting properties. Consumers can quickly verify the authenticity of the products by simply scanning the code with their mobile phones. In a market sampling, the enterprise successfully identified a number of counterfeit products by virtue of the anti-counterfeiting information marked by the laser marking machine, which effectively safeguarded the brand image and consumer rights and interests. In addition, the laser marking machine can also be used to engrave personalised patterns and texts according to customers' needs, meeting the diversified needs of different brands.

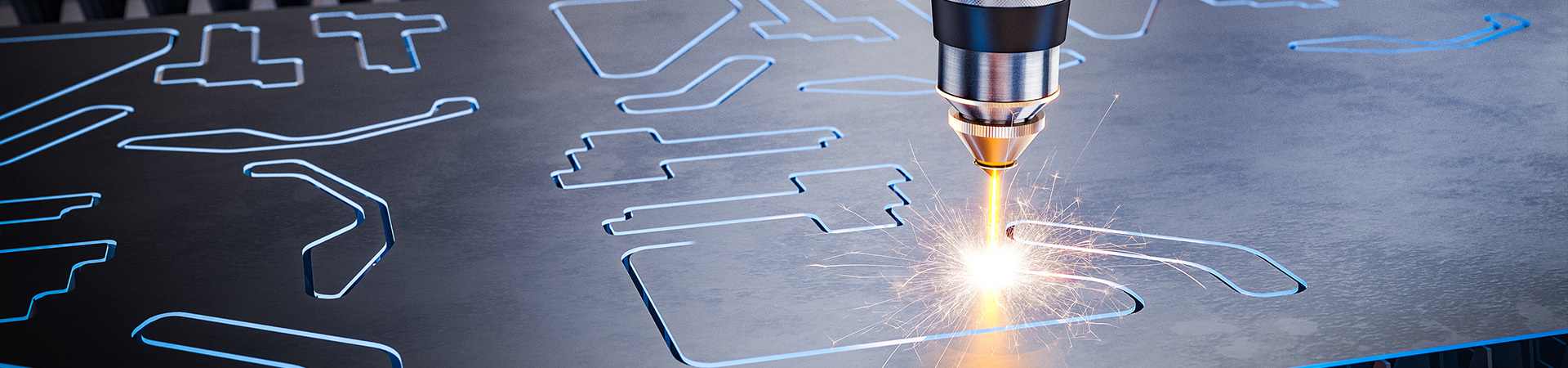

Laser cutting machine: the right hand of packaging design innovation

Packaging design innovation cannot be achieved without precise cutting techniques. In a company specialising in creative packaging design, designers often need to cut various materials into unique shapes to achieve novel packaging forms. While traditional cutting methods struggle to meet the demands of complex shapes and high precision, Udibo laser cutters are able to provide burr-free, high-precision cutting of a wide range of packaging materials, such as paper, cardboard, and plastic film, by precisely controlling the energy and path of the laser beam. When designing a shaped gift box, the laser cutter was able to quickly cut complex folds and curves according to the design drawings, with a cutting accuracy of ±0.08 mm, and the cut material could be assembled directly without much trimming. After adopting the laser cutting machine, the company's packaging design cycle has been shortened by 60%, the design ideas have been better realised, and the competitiveness of the products in the market has been greatly improved.

As a reliable technology partner for the printing and packaging industry, Udibo Industrial Machinery will continue to invest in research and development to optimise the performance and functionality of our laser machines. We are confident that our range of laser machines will help printing and packaging companies to improve productivity, optimise product quality, reduce production costs and stand out in a competitive market. If you are looking for advanced processing solutions in the printing and packaging industry, Udibo looks forward to working with you to create a better future for the printing and packaging industry.

Application scenarios

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Recommend Product

Contact Us

Phone: +86 (China) 152-5267-7152

WhatsApp: +86 (China) 152-5267-7152

E-mail:info@udibomfg.com

Address: Building 1002 Redstar International Technology Park, Mudu Town, Wuzhong District, Suzhou City, Jiangsu Province, China