Electronic Industry

Unlocking the unlimited potential of laser machines in the electrical and electronic industry

With the rapid development of science and technology, the electrical and electronic industry continues to innovate in pursuit of higher precision, efficiency and quality. udibo Industrial Machinery, with its profound accumulation of technology, develops and manufactures laser welding machines, laser cleaning machines, laser marking machines and laser cutting machines, which have demonstrated strong application value in the field of electrical and electronic appliances, and provided key support for the industry's upgrading.

Laser welding machine: master of the art of precision connection

In the manufacturing of electronic appliances, the precision of the connection of parts directly determines the performance of the product. udibo's laser welding machine, with its excellent micron-level welding accuracy, has become the perfect choice for precision connection. In the production workshop of a well-known mobile phone brand, the welding process of mobile phone camera module is being carried out in an orderly manner. The internal structure of the camera module is extremely precise, the traditional welding method is very easy to cause thermal damage, affecting the image quality. But our udibo laser welding machine, with advanced beam control technology, can be completed in a very short period of time, fast, accurate welding, not only high welding strength, but also cleverly avoid the thermal impact on the surrounding sensitive components, so that the brand's mobile phone camera module yield from the previous 85% to 95%. At a laptop motherboard manufacturing site, the welding of memory stick slots to the motherboard requires extreme precision, and the slightest mishap can lead to false soldering, resulting in computer failure. udibo's laser welding machine has helped a laptop maker reduce after-sales failures by 30 per cent by accurately positioning the weld joints to ensure that the slots are securely connected to the motherboard.

Laser cleaners: efficient pioneers in the field of cleaning

During the production of electronic and electrical appliances, tiny contaminants on the surface of components can become ‘time bombs’ that affect product performance. In semiconductor chip manufacturing plants, tiny particles and organic matter on the surface of silicon wafers can seriously affect chip performance. udibo laser cleaners can accurately remove these impurities through precise scanning of high-energy laser beams at the site, guaranteeing a high yield rate for chip manufacturing. A large smart TV manufacturer, in the circuit board production process, soldering residual flux if not thoroughly removed, long-term use may lead to circuit short circuit. Our laser cleaners work in real time on the production line to completely remove flux residues, ensuring stable operation of the TV, which significantly reduces the after-sales repair rate of the enterprise's products. For printed circuit boards (PCBs), the laser cleaning machine can effectively remove flux residues and oxides, improve the electrical performance of the circuit board, and ensure the stable operation of electronic products. Moreover, this non-contact cleaning method, zero damage to precision electronic components, fully meet the high requirements of the electrical and electronic industry.

Laser marking machine: the perfect interpreter of information marking

Product traceability and brand identification are crucial in the electrical and electronic industry. In the production site of smart watches, our udibo laser marking machine is marking the shell of smart watches with delicate brand logos and product models, which not only realises product identification, but also enhances product aesthetics and brand recognition. In smart home equipment production workshops, such as the production line of smart speakers, each product needs to be marked with a unique serial number, which is convenient for after-sales maintenance and quality tracking. udibo laser marking machine, with its fast and efficient marking ability, can complete the marking work of a product within 1 second, which greatly improves the production efficiency, and helps the smart home enterprise to achieve the doubling of production capacity. In the production of mass-produced electronic products, such as Bluetooth headsets, laser marking machine with its fast and efficient characteristics, can complete a large number of products in a short period of time to mark the information, to ensure that each product has a unique identity, to facilitate product management and after-sales tracking.

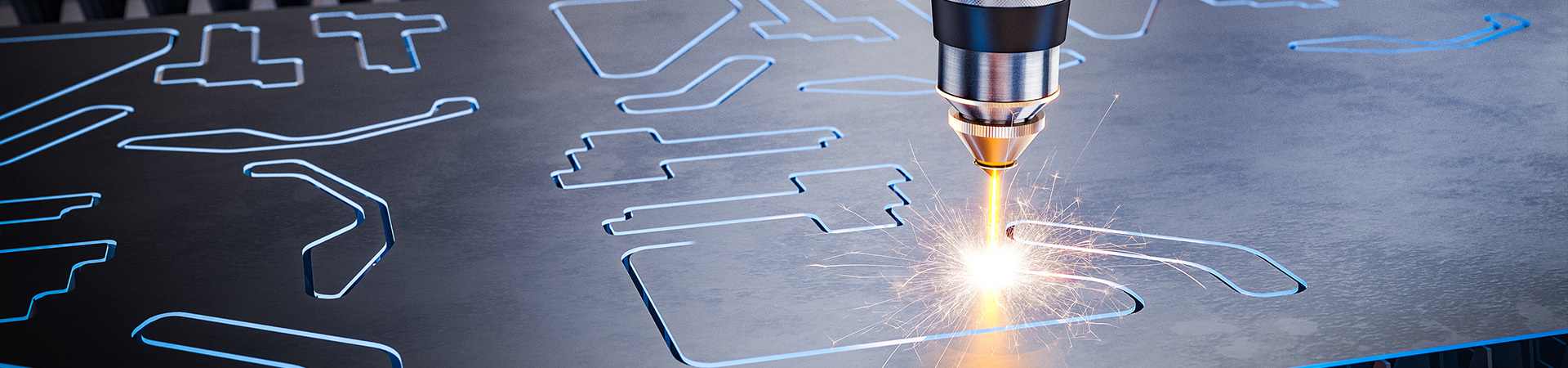

Laser Cutting Machines: An Innovative Force for Precision Processing

Components in the electrical and electronics industry are complex and diverse in shape and require a high degree of cutting precision. In the flexible circuit board (FPC) cutting workshop, udibo laser cutting machine is busy working. It is capable of stress-free cutting, perfectly avoiding the stress damage caused by traditional mechanical cutting, greatly improving the cutting accuracy and yield rate, and reducing the defective rate of an FPC manufacturer from 10% to 3%. In the case of screen bezel cutting for tablet PCs, where high cutting precision is required to ensure a tight fit, the udibo laser cutter is able to cut accurately according to the design requirements, ensuring that the screen bezel dimensions are precise and accurate, which has helped the tablet PC manufacturer to improve the overall quality of its products. For some electronic parts with complex shapes, such as the shaped fins of computer heat sinks, the laser cutting machine can accurately cut them according to the design drawings without the need for moulds, which greatly shortens the research and development cycle, reduces the production cost, and helps the enterprise to seize the first opportunity in the fierce competition in the market.

As an industry leader, udibo Industrial Machinery is always committed to providing better and more advanced laser equipment and solutions for the electrical and electronic industry. Our range of laser machines are being integrated into every aspect of electrical and electronic production, driving the industry to new heights. If you are looking for ways to improve the efficiency and quality of your electrical and electronic production, udibo is ready to work with you to explore the infinite possibilities of laser technology and create a brilliant future for the electrical and electronic industry.

Application scenarios

Sample 1

Sample2

Sample 3

Sample 4

Sample 5

Sample 6

Sample 7

Sample 8

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Recommend Product

Contact Us

Phone: +86 (China) 152-5267-7152

WhatsApp: +86 (China) 152-5267-7152

E-mail:info@udibomfg.com

Address: Building 1002 Redstar International Technology Park, Mudu Town, Wuzhong District, Suzhou City, Jiangsu Province, China