Aerospace Industry

Laser machines: a force for innovation in aerospace

The aerospace industry is a technology-intensive industry that requires precision in the manufacture of components, material properties and product reliability. In this field of challenges and opportunities, Udibo Industrial Machinery's laser welding machines, laser cleaning machines, laser marking machines and laser cutting machines, developed and manufactured by Udibo Industrial Machinery, are becoming a key force in the upgrading of the aerospace industry, thanks to the company's in-depth accumulation of laser technology.

Laser Welding Machines: Creating Robust Aircraft Structures

In the manufacture of aircraft, the connection quality of fuselage frame, wings and other components is directly related to flight safety. A well-known aviation manufacturer in the production of new passenger aircraft, the wing of the aluminium alloy structural parts connection has become a major problem. The traditional welding process has a large heat-affected area, which can easily lead to material deformation and affect the aerodynamic performance of the parts. the Udibo laser welding machine adopts advanced pulsed laser technology to achieve low heat input welding. When welding the wing truss and skin, the width of the weld seam is controlled within 0.3mm, and the heat-affected zone is extremely small, which effectively avoids structural deformation. The strength of the welded parts increased by 25% and the fatigue life was extended by 30%. After the introduction of the laser welding machine, the production cycle of the new airliner was shortened by 20%, and the performance indexes were excellent in the flight test.

Laser cleaning machine: to protect the performance of aviation equipment

Aero-engine, spacecraft parts in service, the surface will accumulate oil, oxide layer and corrosion products, seriously affecting the performance of equipment. In an aero-engine repair facility, the surface of engine blades to be repaired is covered with high-temperature oxidised layers and carbon deposits, which are precisely removed by Udibo's laser cleaners using a high-energy-density laser beam. Compared with traditional chemical cleaning, laser cleaning requires no chemical reagents, avoiding environmental pollution and corrosion of materials. The surface roughness of the cleaned blades meets the original factory standard, and the performance of the repaired engine is restored to the level of a new one, with a 35% reduction in repair costs and a 15-day shorter repair cycle.

Laser marking machine: realising full life cycle traceability of products

The quality traceability and marking management of aerospace products are crucial. On the production line of spacecraft components, Udibo laser markers mark each key component with a QR code containing information such as the production batch, serial number, and production date. These markings are laser-etched to a uniform depth and remain legible in extreme environments such as high temperatures and pressures. In a spacecraft fault troubleshooting, technicians through the laser marking machine marked two-dimensional code, quickly locate the faulty parts of the production batch and related process parameters, to quickly solve the problem provides a key basis for effectively reducing the spacecraft maintenance costs and risks.

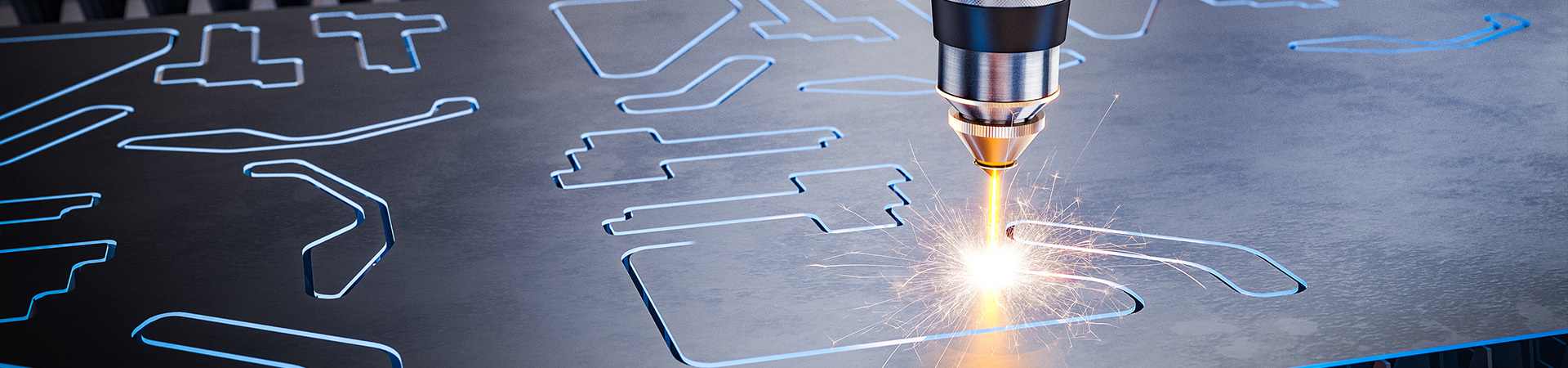

Laser cutting machine: help complex parts precision processing

Complex and diverse shapes of parts in the aerospace field require high cutting precision and surface quality. In a factory producing turbine blades for aero-engines, Udibo laser cutting machines are cutting high-temperature alloy materials. Conventional cutting methods are difficult to meet the complex curved surfaces and high precision requirements of turbine blades, as well as high material loss. The Udibo laser cutter precisely controls the path of the laser beam, enabling stress-free, high-precision cutting of high-temperature alloys with an accuracy of ±0.03 mm. The surface quality of the cut blades is so good that there is no need for subsequent grinding, which improves material utilisation by up to 40 per cent and increases productivity by up to three times.

As a reliable technology partner to the aerospace industry, Udibo Industrial Machinery will continue to innovate and improve the performance and stability of its laser machines. We believe that with our advanced laser machine series, we can help aerospace companies break through technical bottlenecks, improve product quality and productivity, and jointly promote the aerospace industry to new heights. If you are looking for advanced processing solutions in the aerospace field, Udibo is looking forward to working with you to create a brilliant future.

Application scenarios

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Recommend Product

Contact Us

Phone: +86 (China) 152-5267-7152

WhatsApp: +86 (China) 152-5267-7152

E-mail:info@udibomfg.com

Address: Building 1002 Redstar International Technology Park, Mudu Town, Wuzhong District, Suzhou City, Jiangsu Province, China