Healthcare Industry

Laser machines: Drivers of innovation in the medical industry

In the medical industry, precision, safety and efficiency have always been the core pursuit of technological development, and Udibo Industrial Machinery, with its excellent laser technology research and development strength, has introduced laser welding machines, laser cleaning machines, laser marking machines and laser cutting machines, which are gradually penetrating into all aspects of the medical field and providing a powerful boost to the innovative development of the medical industry.

Laser welding machine: the key to precision manufacturing of medical devices

In the production of medical devices, many parts need to be connected with high precision to ensure the performance and reliability of the instruments. Tweezers for minimally invasive surgery are being produced in a well-known surgical instrument manufacturing facility. The heads of these tweezers are extremely delicate, and traditional welding methods make it difficult to ensure the quality of the weld, which can lead to weak or deformed weld joints that can interfere with surgical operations. the Udibo laser welding machine utilises a high-energy-density laser beam to achieve precise welding of tiny components. When welding the head and handle of the forceps, the width of the weld is only 0.1mm, but the strength of the weld is 30% higher than traditional welding methods. This not only ensures the durability of the tweezers, but also makes them more flexible and precise to operate. After adopting our laser welding machine, the yield rate of the company's surgical instruments increased from 75% to 90%, effectively reducing production costs.

Laser Cleaner: Ideal for Medical Equipment Maintenance

During long-term use, medical equipment accumulates dirt, bacteria and impurities on the surface and inside, which may affect the normal operation and testing accuracy of the equipment, and even pose a threat to the health of patients. In the laboratory department of a large hospital, a blood analyser that had been in use for many years had a large amount of dust and biological residues attached to its internal optics, which were efficiently cleaned by Udibo's laser cleaner through precise control of the laser beam, without dismantling the equipment. Unlike traditional manual wiping and chemical cleaning methods, laser cleaning does not scratch or corrode the optics and restores the inspection accuracy of the equipment. According to statistics, the use of laser cleaning machine maintenance of medical equipment, equipment failure rate reduced by 40%, the maintenance cycle has been extended two times, for the hospital to save a lot of equipment maintenance costs.

Laser Marking Machine: Reliable Guarantee for Tracing and Marking of Medical Products

In the medical industry, it is crucial to accurately mark and trace medical devices and drugs, which is related to patient safety and medical quality control. On the production line of a pharmaceutical company, Udibo laser markers are clearly marking drug boxes with production dates, batch numbers, QR codes and other information. These markings are permanently etched by the laser and remain legible even in harsh environments such as humidity and high temperatures. In the event of a drug recall, the information marked by the laser marking machine enables companies to quickly locate the drug in question, greatly shortening the recall time and reducing potential risks. In addition, in the production of medical devices, laser marking machine can also be used to mark the product model, instructions for use and other important information, to facilitate the operation of medical personnel and equipment management.

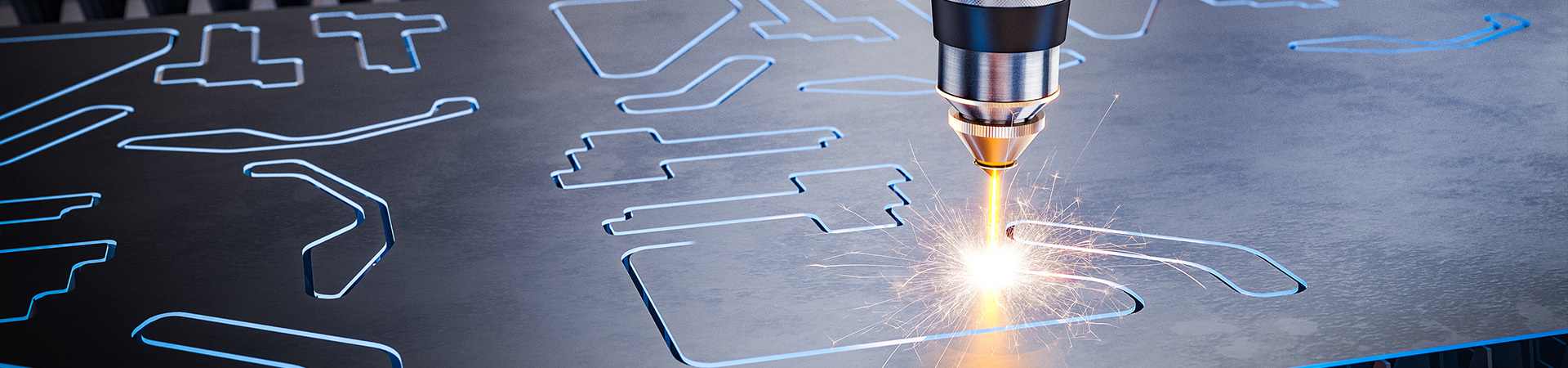

Laser Cutting Machines: The Right Hand for Personalisation of Medical Consumables

Medical consumables come in many varieties and often need to be personalised according to individual patient differences. In a factory producing customised dentures, Udibo laser cutting machines are used to cut the raw material for dentures. Whereas traditional cutting methods have difficulty in meeting the requirements of complex shapes and high precision, the laser cutter, by precisely controlling the energy and path of the laser beam, enables burr-free, high-precision cutting of the material according to the patient's model of the oral cavity, with a cutting accuracy of ±0.05 mm. The cut denture can then be directly processed and assembled without the need for excessive grinding and trimming. After adopting the laser cutting machine, the production cycle of the enterprise's denture has been shortened by 50%, the fit and comfort of the product have been greatly improved, and the patient satisfaction rate has reached over 95%.

As a reliable technology partner for the medical industry, Udibo Industrial Machinery will continue to invest in research and development to continuously optimise the performance and functionality of our laser machines. We are confident that our range of lasers will help medical companies to improve productivity, ensure product quality and reduce operating costs, thus contributing to the technological advancement of the medical industry. If you are looking for advanced processing solutions in the medical field, Udibo looks forward to working with you to create a better future for the medical industry.

Application scenarios

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Recommend Product

Contact Us

Phone: +86 (China) 152-5267-7152

WhatsApp: +86 (China) 152-5267-7152

E-mail:info@udibomfg.com

Address: Building 1002 Redstar International Technology Park, Mudu Town, Wuzhong District, Suzhou City, Jiangsu Province, China