Shipbuilding Industry

Laser technology empowers shipbuilding, opening a new chapter in the industry

In the large and complex industry of shipbuilding, accurate, efficient and reliable processing technology is always the key to promote the progress of the industry. Udibo Industrial Machinery, with its profound accumulation in the field of laser equipment, develops and manufactures laser welding machines, laser cleaning machines, laser marking machines and laser cutting machines, which are gradually changing the traditional mode of shipbuilding and bringing brand new development opportunities for the industry.

Laser welding machine: the creator of strong hulls

The hull structure of the ship needs to withstand huge water pressure and external forces, welding quality is directly related to the safety performance and service life of the ship. In the production workshop of a large shipyard, a 10,000-tonne cargo ship is under construction. Traditional welding methods are inefficient and the quality of the weld is difficult to ensure, prone to cracks, etc. The Udibo laser welding machine uses a high energy density laser beam to achieve fast, high quality welding. When welding the deck of a cargo ship, the laser welding machine is able to complete a long weld seam in one go, with a uniform and solid weld seam and a 20% increase in strength compared to traditional welding methods. In addition, the laser welding process has a small heat-affected zone, which reduces the distortion of the plate and drastically shortens the time and cost of the subsequent correction process. Shipyards using our laser welding machines have been able to shorten the construction period of a single ship by 15 per cent and reduce the rate of weld quality defects by 50 per cent.

Laser cleaner: a powerful assistant for ship maintenance

Ships operate in the marine environment for a long time, the surface of the hull will be attached to a large number of marine organisms, rust and oil, these pollutants not only affect the speed of the ship, but also accelerate the corrosion of the hull. Udibo's laser cleaners are used in the dockyard where ships are regularly maintained. The hull of a passenger ship, which had been in service for many years, was covered with a thick layer of rust and shellfish organisms. The laser was able to instantly vaporise or strip away these contaminants through the use of a high-energy laser beam, eliminating the need for chemical cleaning agents and avoiding pollution of the marine environment. The cleaned hull surface is as good as new, effectively restoring the ship's navigational performance. According to statistics, the use of laser cleaning machine for ship maintenance, annual savings due to reduced speed and increased fuel consumption of about 30%, and at the same time reduce the damage to the hull anticorrosion coating, extending the service life of the coating.

Laser Marking Machine: Intelligent Steward of Information Management

Shipbuilding involves many parts and equipment, and clear and accurate marking is crucial for product traceability, quality control and post maintenance. In the ship engine manufacturing workshop, Udibo laser marking machines are marking key engine components with unique identification codes. These codes contain important information such as production date, batch and model number, and the laser marking creates a permanent marking that is clear, wear-resistant and can be preserved for a long time, even in harsh marine environments. During the construction of a container ship, a large number of pipes and valves need to be marked, and the laser marking machine is able to quickly and accurately complete the marking task to ensure that each component has a clear identity. This makes the ship in the later maintenance and overhaul, the staff can quickly locate the problematic parts, improve the maintenance efficiency and reduce the maintenance cost.

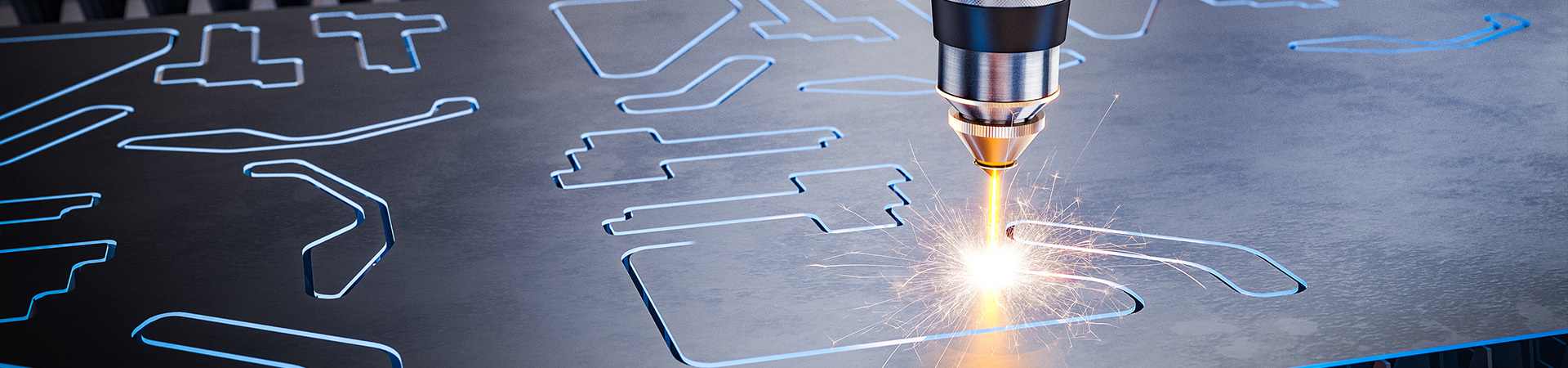

Laser Cutting Machine: Precision Craftsman for Complex Parts

Shipbuilding requires a large number of parts with complex shapes, such as propellers and hull structural parts, which have extremely high requirements for cutting precision and quality. At a factory specialising in marine propellers, Udibo laser cutting machines cut high-strength alloy materials according to complex design drawings. While traditional cutting methods make it difficult to ensure the precision and surface quality of propeller blades, the laser cutter achieves burr-free, high-precision cutting by precisely controlling the energy and path of the laser beam. The cut propeller blades do not require secondary processing and go directly into the subsequent assembly process. After adopting the laser cutting machine, the production efficiency of propellers has been increased by 30% and the scrap rate has been reduced by 40%, which saves a lot of raw materials and production costs for the enterprise.

As a strong partner to the shipbuilding industry, Udibo Industrial Machinery will continue to work in the field of laser technology to innovate and optimise the performance of its products. We firmly believe that our laser equipment can help shipbuilders to improve production efficiency, reduce costs and improve product quality, and together we will sail to a new glory in the shipbuilding industry. If you are looking for efficient solutions in the field of shipbuilding, Udibo is looking forward to working with you to create a bright future.

Application scenarios

Degreasing

Descale

Oxide-removal

Paint-stripping

Part-Coating-Pretreatment

Rubber-Abrasives

Stone-Statue-Cleaning

Tire-Abrasives

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Recommend Product

Contact Us

Phone: +86 (China) 152-5267-7152

WhatsApp: +86 (China) 152-5267-7152

E-mail:info@udibomfg.com

Address: Building 1002 Redstar International Technology Park, Mudu Town, Wuzhong District, Suzhou City, Jiangsu Province, China