Energy Industry

Laser machines: innovation engines for the new energy sector

Against the backdrop of the global energy transition, the new energy industry is booming, and the need for efficient and precise production technology is becoming increasingly urgent. Udibo Industrial Machinery, with its excellent R&D capabilities in laser technology, is empowering all aspects of the new energy industry with its laser welding, laser cleaning, laser marking and laser cutting machines, injecting a strong impetus for innovation and development in the industry. Laser welding machine: the new energy battery manufacturing

Laser welding machine: the key link of new energy battery manufacturing

The performance and safety of new energy batteries are directly related to the use of new energy equipment. In the workshop of a large lithium battery manufacturer, the laser welding machine is busy working. The connection between the pole piece and electrode of lithium battery requires high welding precision and strength. Traditional welding methods are prone to false welding, short-circuit and other problems, affecting the battery's charging and discharging performance and service life. Udibo laser welding machine uses a high-energy-density laser beam to achieve precise welding of the pole piece and electrode. The width of the weld seam is as narrow as 0.2mm, but the welding strength far exceeds the industry standard, which greatly improves the stability and safety of the battery. After adopting our laser welding machine, the yield rate of lithium batteries of this enterprise has increased from 80% to 92%, and the production efficiency has been improved by 35%, which significantly reduces the production cost and enhances the competitiveness of the products in the market.

Laser cleaning machine: PV module production of clean guards

In the production process of photovoltaic modules, the pollutants on the surface of silicon wafers will seriously affect the photoelectric conversion efficiency of photovoltaic cells. At a photovoltaic company's production site, the surface of freshly cut wafers is covered with cutting fluids, dust and metal impurities, which are quickly removed by the Udibo laser cleaner through precise control of the laser beam, without damaging the wafers. Compared to traditional chemical and ultrasonic cleaning methods, laser cleaning eliminates the use of chemicals, avoids environmental contamination, and improves cleaning efficiency by up to 50%. After laser cleaning of silicon wafers, made of photovoltaic modules photoelectric conversion efficiency increased by 3%, for photovoltaic enterprises to bring higher power generation revenue.

Laser marking machine: new energy product traceability and quality control of reliable partners

In the new energy industry, product quality traceability and marking management is crucial. In a new energy automobile motor production line, Udibo laser marking machine is marking each motor casing with a unique identification code, including production date, batch number, product model and other information. These markings are permanently etched by the laser and are clearly recognisable even in harsh environments. Once the product quality problems, enterprises can quickly trace back to the production process through the identification code, and take timely measures to solve the problem. In a market sampling, the enterprise with the laser marking machine marked information, successfully passed the quality inspection, effectively maintaining the brand image of the enterprise. In addition, the laser marking machine can also be used for new energy battery module marking, convenient battery management and maintenance.

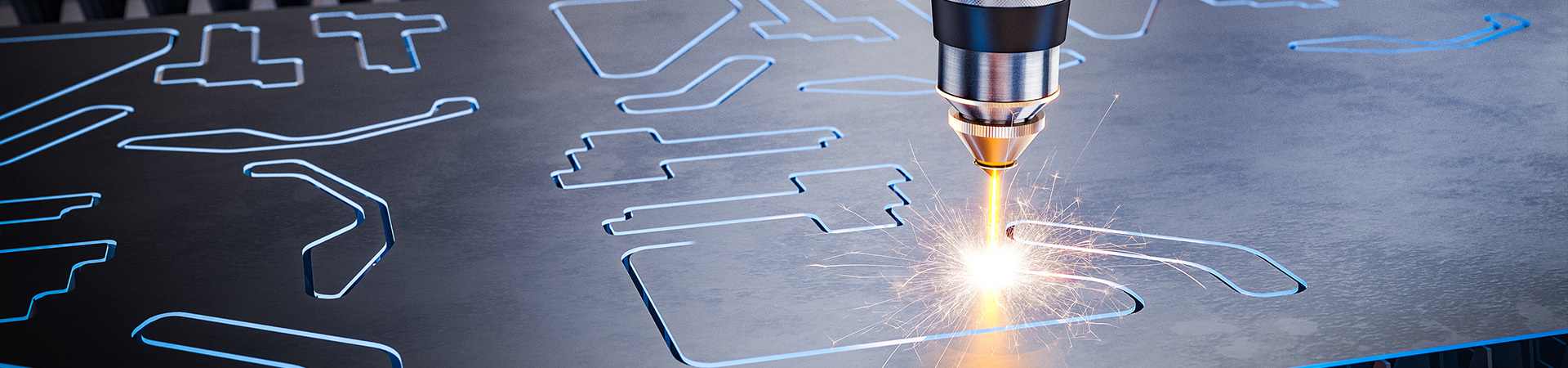

Laser cutting machine: precision craftsmen of new energy equipment parts processing

New energy equipment parts are often complex shape, the cutting precision requirements are extremely high. At a wind turbine blade manufacturing plant, Udibo laser cutting machines are cutting carbon fibre composite materials. Traditional cutting methods make it difficult to ensure cutting accuracy and surface quality, and can lead to material waste. The laser cutting machine through precise control of the laser beam energy and path, can be on the carbon fibre composite materials for burr-free, high-precision cutting, cutting accuracy of up to ± 0.05mm. after cutting the blade parts without secondary processing, directly into the subsequent assembly process. After adopting the laser cutting machine, the production cycle of wind turbine blades of this enterprise has been shortened by 45%, and the material utilisation rate has been increased by 30%, which greatly reduces the production cost and improves the production efficiency.

As a committed technology partner for the new energy industry, Udibo Industrial Machinery will continue to invest in research and development to optimise the performance and functionality of our laser machines. We firmly believe that through our laser machine series products, we can help new energy enterprises to improve production efficiency, guarantee product quality, reduce production costs, and jointly promote the new energy industry to new heights. If you are looking for advanced processing solutions in the field of new energy, Udibo is looking forward to working with you to create a brilliant future for the new energy industry.

Application scenarios

Clutch-plate-cleaning

Gear-Oil-Cleaning

Grease-cleaning

Metal-Surface-Paint-Cleaning

Rust-removal-and-cleaning-of-parts

Screw-Cleaning

Tyre-mould-cleaning

Weld-Cleaning

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Recommend Product

Contact Us

Phone: +86 (China) 152-5267-7152

WhatsApp: +86 (China) 152-5267-7152

E-mail:info@udibomfg.com

Address: Building 1002 Redstar International Technology Park, Mudu Town, Wuzhong District, Suzhou City, Jiangsu Province, China