Mold Industry

Laser machine: innovation booster for the mould industry

The mould and die industry, as the basis of industrial production, has extremely high demands on processing precision, productivity and mould life. In this highly competitive field, Udibo Industrial Machinery, with its leading laser technology, develops and manufactures laser welding machines, laser cleaning machines, laser marking machines and laser cutting machines, which are gradually becoming a powerful assistant in mould manufacturing and maintenance, helping enterprises to enhance their core competitiveness.

Laser welding machine: repair and manufacture of solid protection

In the process of mould manufacturing and use, there will often be mould wear and tear, rupture and other situations that need to be repaired. In an auto parts mould manufacturing enterprise, a set of large-scale moulds used for the production of automobile bumpers appeared partial wear, affecting the product's forming quality. Traditional welding repair methods tend to cause deformation of the mould, affecting the accuracy of subsequent production. the Udibo laser welding machine uses pulsed lasers with high energy density to accurately weld and repair the worn parts. During the welding process, the heat input is extremely small, effectively avoiding mould deformation. The surface flatness of the repaired mould is controlled within 0.05mm, and after re-use test, the life of the mould has been extended by 40%, and the dimensional accuracy and surface quality of the bumper produced have reached the industry's high standard. In addition, in the manufacture of some complex structure of the mould, laser welding machine can achieve precision welding of different material parts, enhance the overall strength of the mould, to meet customer demand for high performance mould.

Laser cleaning machine: efficient tool for mould cleaning

Moulds in the process of use, the surface will be attached to the release agent, oil, metal shavings and other pollutants, these pollutants not only affect the mould release effect, but also reduce the service life of the mould. In a plastic mould factory, where the surface of freshly used injection moulds is covered with release agents and plastic residues, the Udibo laser cleaner uses a high-energy laser beam to instantly vaporise or strip away these contaminants. Compared with traditional chemical cleaning and manual wiping methods, laser cleaning efficiency is increased by 60%, and no chemical reagents are required, avoiding environmental pollution and corrosion of the mould surface. After cleaning the mould surface cleanliness, subsequent production of plastic products smooth release, defective rate reduced by 30%.

Laser Marking Machine: Reliable Partner for Mould Identification and Traceability

In mould management, clear marking and tracing of moulds is crucial, which helps enterprises in production management and quality control. On the production floor of an appliance mould manufacturer, Udibo laser marking machines are marking each mould with a unique identification code, including the mould number, date of manufacture, applicable product model and other information. These markings are permanently etched by the laser and will not fade or wear out even after long periods of use and frequent opening and closing of the moulds. In a product quality problem troubleshooting, through the laser marking machine marking information, the enterprise quickly locate the corresponding mould, and the production parameters of the mould and the use of a detailed analysis, a quick solution to the product quality problems, and effectively reduce the production cost and production cycle.

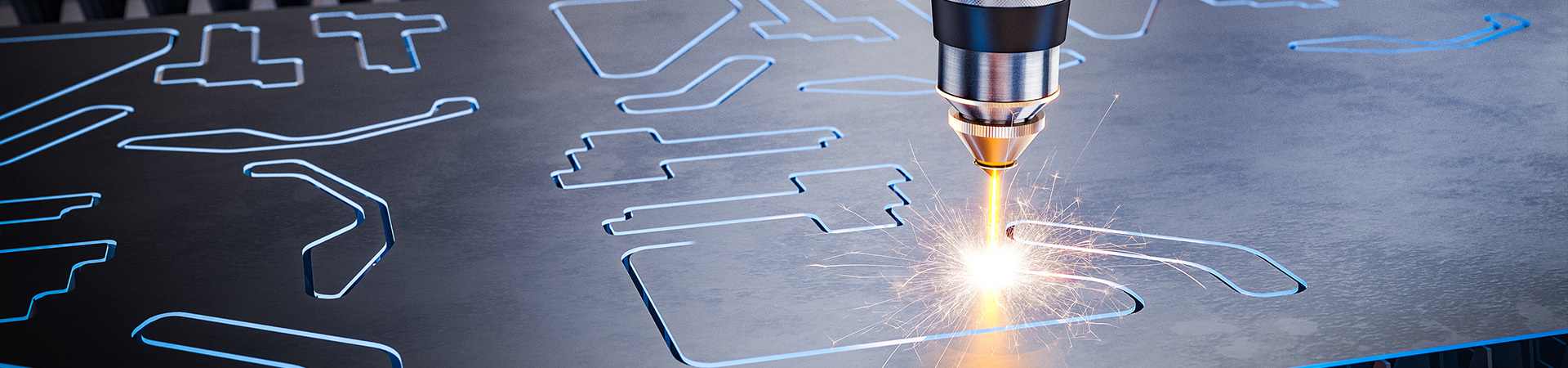

Laser Cutting Machine: Precision Craftsman for Complex Mould Processing

The shape and structure of moulds are often complex and varied, and the requirements for cutting precision are extremely high. At a precision mould processing plant, a Udibo laser cutter is being used to cut mould steel to create a complex core for a mobile phone casing mould. Traditional cutting methods make it difficult to ensure the accuracy of complex shapes and can lead to material wastage. The Udibo laser cutter precisely controls the energy and path of the laser beam through an advanced CNC system, enabling burr-free, high-precision cutting of the mould steel with a cutting accuracy of ±0.02mm. After cutting the core without a lot of subsequent processing, directly into the assembly process. After adopting the laser cutting machine, the production cycle of the enterprise's moulds has been shortened by 50%, and the material utilisation rate has been increased by 35%, which greatly reduces the production cost and enhances the competitiveness of the products in the market.

As a reliable technology partner for the mould and die industry, Udibo Industrial Machinery will continue to invest in research and development to continuously optimise the performance and functionality of our laser machines. We firmly believe that through our laser machine series products, we can help mould manufacturing enterprises to improve production efficiency, guarantee the quality of moulds, reduce production costs, and jointly promote the mould industry to a new height. If you are looking for advanced processing solutions in the mould and die field, Udibo is looking forward to working with you to create a better future for the mould and die industry.

Application scenarios

Clutch-plate-cleaning

Gear-Oil-Cleaning

Grease-cleaning

Metal-Surface-Paint-Cleaning

Rust-removal-and-cleaning-of-parts

Screw-Cleaning

Tyre-mould-cleaning

Weld-Cleaning

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Recommend Product

Contact Us

Phone: +86 (China) 152-5267-7152

WhatsApp: +86 (China) 152-5267-7152

E-mail:info@udibomfg.com

Address: Building 1002 Redstar International Technology Park, Mudu Town, Wuzhong District, Suzhou City, Jiangsu Province, China